Temperature Sensing Solutions

Tempsens provides a comprehensive range of temperature sensing solutions engineered for accuracy, durability, and reliable performance in demanding industrial environments. Their portfolio includes high-quality thermocouples, RTDs, infrared sensors, and customized temperature probes designed to deliver precise measurement and stable operation under extreme conditions. With deep technical expertise and strong manufacturing capability, Tempsens supports critical process control across industries such as metal processing, power generation, petrochemicals, pharmaceuticals, and research laboratories—ensuring consistent, accurate temperature monitoring where it matters most.

Thermocouples

Thermocouples have been the preferred temperature sensors in industries where precision is vital for operations. Thermocouples can detect temperatures ranging from -200°C to 2320°C across extreme industrial conditions. At Tempsens, our journey as one of the top thermocouple manufacturers has been about building trust through uncompromising performance.

Tempsens’ range features base metal thermocouples, MI thermocouples, noble metal thermocouples, refractory thermocouples, and tailored assemblies for high-vibration, high-temperature, and hazardous environments.

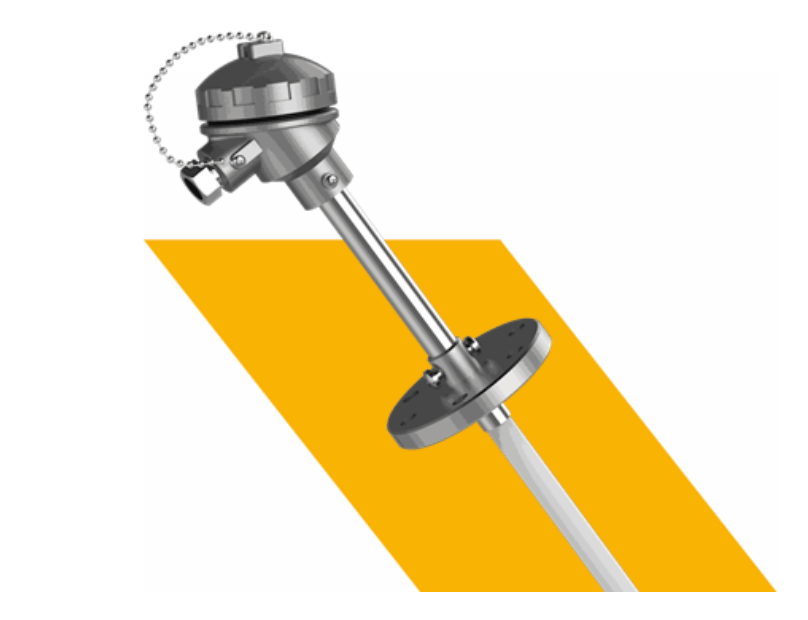

Resistance Temperature Detector

Tempsens RTD resistance temperature detectors are trusted when you need accurate and repeatable temperature reading.Commonly known as resistance temperature devices, these sensors are used in industries where stable, reliable performance matters – like power plants and pharma labs.

Whether you need a platinum resistance temperature sensor for precise lab work or tough industrial jobs with vibration & heat, Tempsens RTD resistance temperature detectors are built to deliver reliable results every time.

Thermowells and Accessories

Tempsens offers a robust selection of thermowells and temperature sensor accessories designed to protect sensing elements and ensure accurate, reliable measurement in demanding process environments. Manufactured from high-quality materials and available in a wide range of configurations, Tempsens thermowells provide superior resistance to pressure, flow, corrosion, and mechanical stress. Complemented by a full suite of fittings, connectors, and mounting accessories, these solutions enhance sensor longevity, simplify installation, and maintain system integrity across industries such as petrochemicals, power generation, pharmaceuticals, and industrial processing.

Temperature and Pressure Gauges

At Tempsens, we know that every PSI, every degree, every one of those measurement points is relative. The reason we have created a complete line of temperature and pressure gauges that exceed industry standards, is because we make them for the professionals that simply will not accept anything less than an accurate, durable, and reliable product.

Gauges have grown from a product of the manufacturing floor into a stalwart of the industry. They have emerged as the unsung heroes that aid the operational goals, and the silent defenders of safety of company value. Gauges are not simply products; they have become trusted companions to operators to make split-second decisions that protect equipment and personnel.

Infrared Pyrometers

A pyrometer is a temperature measurement device that does not require contact with the target surface. Instead, it detects and quantifies the thermal radiation emitted by the surface itself. The measurement of temperature based on this principle is called pyrometry. Pyrometers are based on blackbody radiation, which states that the intensity of the radiation emitted is fundamentally related to the surface temperature.

The accuracy of the measurement response is significantly impacted by the emissivity of the target material determining the apparent brightness detected by the pyrometer. Pyrometers are widely used in industry because of their simplicity, rapid temperature response, accuracy, low-cost and reliability in process measurements. Pyrometers are utilized in many applications such as metallurgy, ceramics, and monitoring furnaces.

Online Thermal Imagers

Thermal Imager (Thermal Imaging Camera), or Infrared Thermography Cameras, are powerful tools engineered to visualize the heat signatures around us — but remain unseen by the naked eye. Every object, whether living or inanimate, emits infrared energy, commonly called heat. These cutting-edge infrared thermal camera devices detect infrared radiation, whether it’s emitted directly or reflected off surfaces, and translate it into a visible image called a thermogram.

A thermogram accurately shows variations in temperature with high precision, enabling users to diagnose problems, monitor conditions, and make informed decisions without contact or disruption. From electrical inspections and industrial process monitoring to building diagnostics and medical screening, thermal imaging cameras are changing how we perceive and address issues.

Furnace Monitoring Camera

A furnace monitoring camera system is a specialized type of industrial-grade equipment used to provide real-time visual and thermal assessment of the furnace, boiler, and other high temperature, combustion application environments; primarily, firing or heating chambers. These systems are designed to withstand harsh environments and extreme numbers of heat, ensuring continuous monitoring, thus improving safety and productivity within industry processes.

Temperature Calibrators & Services

Tempsens is a leading manufacturer of temperature calibration equipment and services, providing a wide range of Temperature Calibrators that ensure precise and dependable temperature measurements.

We provide Liquid Bath Calibrators, Dry Block Calibrators, Blackbody Calibrators, Reference Junctions, and Master Sensors that are all specifically designed to meet the customized requirements of temperature-sensitive applications.