Electrical heating solutions

Tempsens offers reliable electrical heating solutions engineered for precise temperature control and efficient heat transfer in industrial environments. With options such as heating cables, flexible heaters, and immersion heaters, these systems deliver uniform heating, long service life, and dependable performance across a wide range of processes and applications.

Process Heaters

Process heaters, as the name suggests, are heaters that are in direct contact with the process.

In these types of heaters, the process fluid enters from one end and this, in turn, passes through the heater, and the heat generated by the heater is transferred to the process fluid through convection or radiant heat transfer, and the process fluid leaves from the other end.

Furnace Heaters

In industrial thermal processing, there can be no compromise; there must be precision, reliability, and repeatability in results. Tempsens products deliver exactly what today’s industries demand, no matter the challenge. For high requirement process situations like annealing, galvanizing, heat treatment, and ultra-high temperature process situations, our heaters can produce temperatures of up to 1100°C.

Every Tempsens furnace heating system is the result of exceptional engineering know-how and expertise in metallurgy. Thermal furnace heating systems provide reliable and efficient heat transfer, no matter if you are running a continuous production process or processing specialized thermal cycles. We will maximize the service life of the furnace while providing reliability of performance in your specialized process.

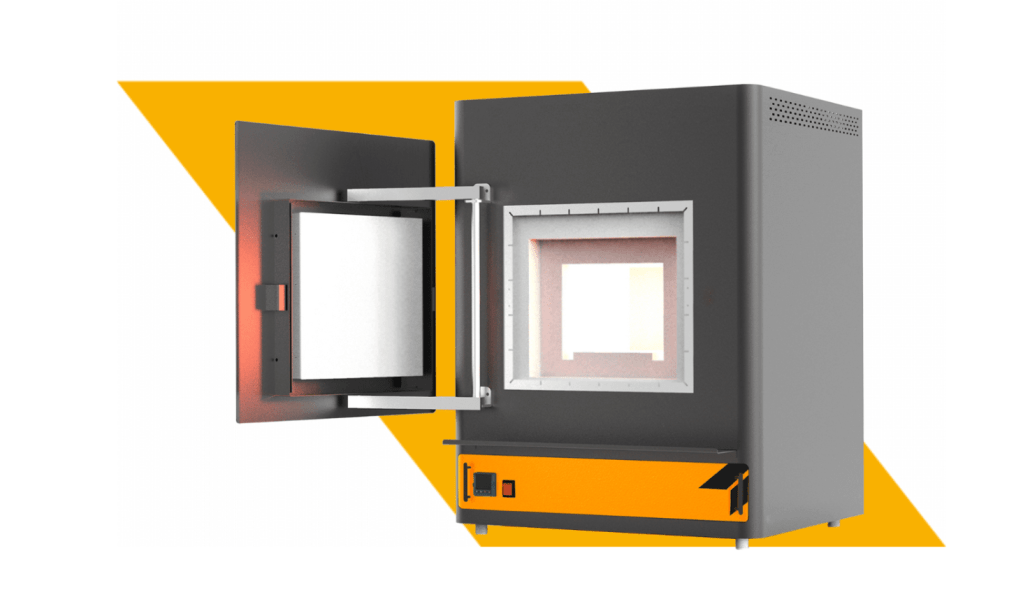

Lab and Process Furnace

At Tempsens, we manufacture a wide range of Lab and Process Furnaces designed for diverse applications such as sintering, annealing, tempering, and calcination. Our furnaces and ovens are available in various sizes and can be customized to meet specific application needs, offering a temperature range of 50-3000°C, ensuring optimal performance & efficiency.

Comfort Heating Solutions

Comfort heating solutions stand out as an option when discomfort issues replicate across domestic applications due to the inefficiencies and ineffectiveness of traditional heating. Older systems provide inaccurate heating that consumes energy and fails when it is needed most. Tempsens floor heating mats and underfloor heating cable technologies remove these limits by implementing a proactive thermal solution without being visible in your structures.

Homeowners are discovering that many of the underfloor/embedded heating systems being implemented are producing demonstrative strategic improvements in comfort and energy efficiency by reducing energy use, eliminating (emergency) repairs, and increasing comfort. Advanced smart cable heated de-icing systems prevent the potentially dangerous accidents caused by ice, while using underfloor heating mats creates a temperature-controlled environment. These technologies from Tempsens don’t just heat an area; they improve daily living through intelligent temperature regulation relative to real-time conditions.

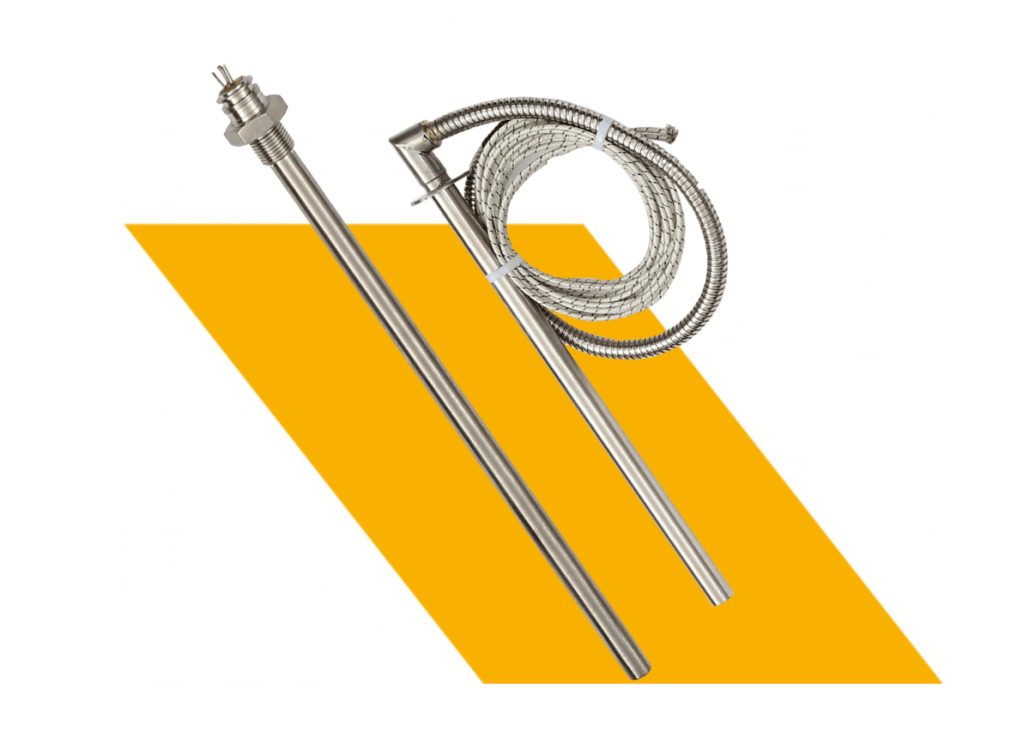

Cartridge Heaters

Hot Rod Cartridge Heaters are designed to provide uniform heating and excellent heat transfer rate throughout the heating surface. Facilitated with individually controllable heating zones, various process requirements such as zone-specific heating and distributed wattage requirements can be achieved with precise and uniform temperatures.

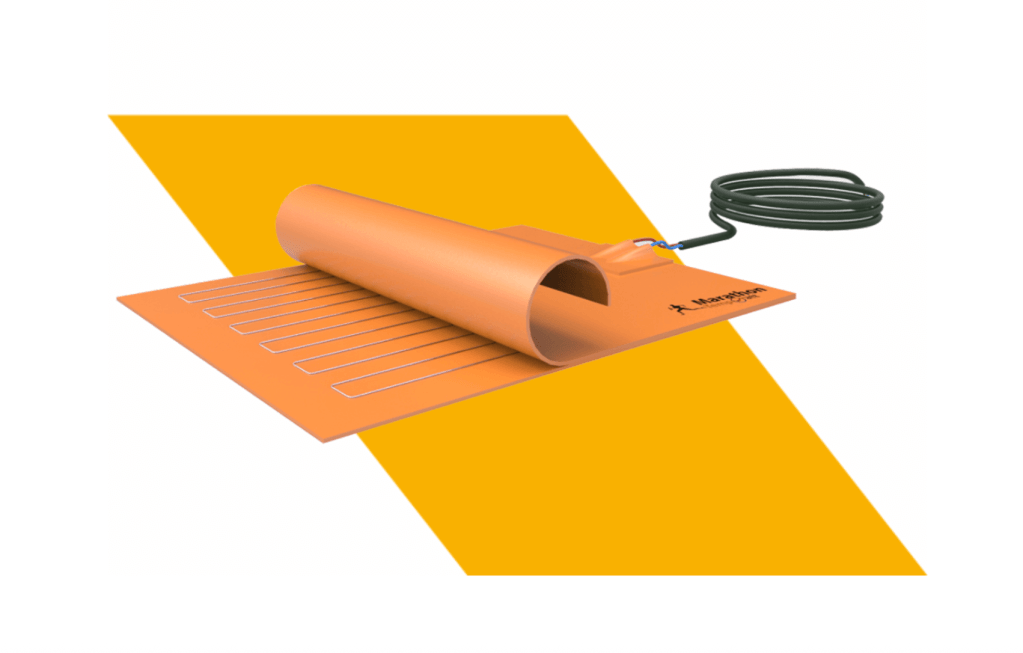

Flexible Heaters – Silicon Rubber Heaters

Flexible silicone rubber heaters are a game-changer in thermal management technology; they provide engineers with flexibility in heating applications where conventional heaters can’t withstand the working conditions. Designed through complex molding processes, flexible heaters place etched-foil or wire-wound material between several layers of high-temperature silicone rubber elastomer, creating heating solutions that fit uneven surfaces and provide even heat across complex geometries.

Flexible silicone heaters operate effectively in temperatures ranging from -60°C to +200°C (with continuous duty up to 230°C for special grades) and are ideal for thermal control with requirements for accuracy, environmental resistance, and design flexibility. Their moisture-sealed construction provides dielectric strength above 1500V and enables inherent chemical resistance, and is relied upon across a range of industries from manufacturing medical devices to protecting aerospace components. Whether you are preventing freeze damage in fluid circuits, maintaining viscosity in a pass of industrial processing, or providing stable temperature profiles to analytical instrumentation, Tempsens flexible heaters are able to provide energy-saving solutions where conventional rigid heaters cannot.

Tubular Heater

Every industry in today’s world is utilizing some or other form of heating applications. The heating is very much a part of our day-to-day life. As the dependency on heating applications grows, there is a serious concern also expressed related to safety and environmental impact, as well as the efficiency of many of the heating solutions being used. While some of the systems have a risk of fire accidents, many of the other conventional systems generate a lot of carbon dioxide and other gases that contaminate the environment.

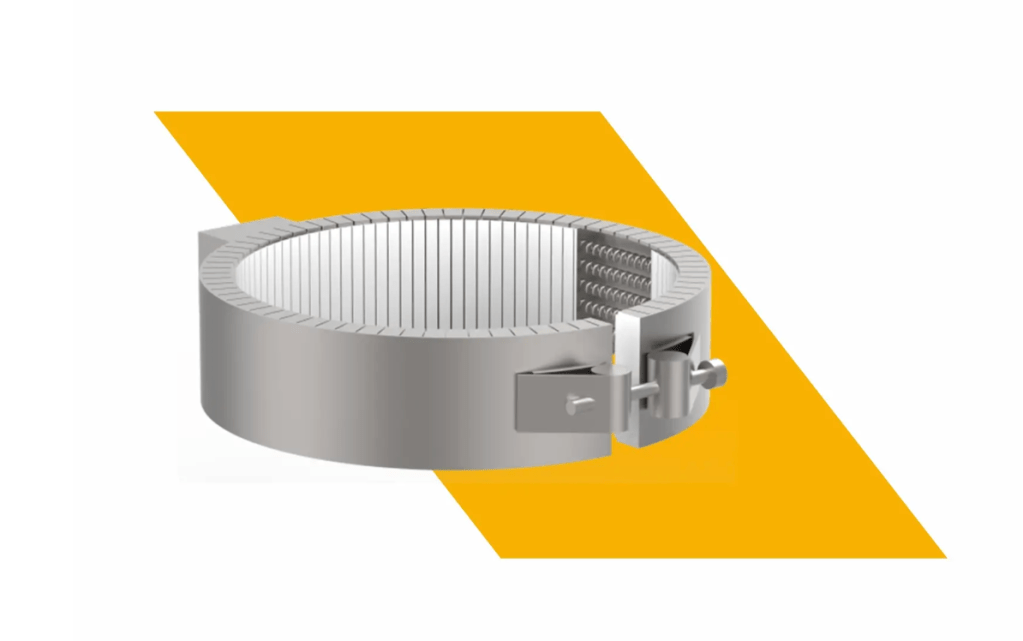

Ceramic Band Heater

Ceramic band heaters are medium-to-high temperature heaters that have 648°C as a maximum working temperature. These durable heaters can have optional in-built ceramic fiber jackets that make them energy efficient. Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. In a ceramic band heater, a nickel-chrome wire is embedded in a flexible outer wall made of special, interlocking ceramic tiles (KNUCKLES), which are assembled like a brick wall.

Mica Band Heater

Mica band heaters offer efficient and economical solutions for heating cylindrical surfaces that require external indirect heating. They are an ideal solution for high-watt-density and high-temperature applications. It uses a nickel chromium resistance strip as a heating element, which is precisely wound on a dielectric material for even heat distribution. The heating element is insulated within a mica core enclosed in a metal sheath, which provides exceptional insulation, dielectric strength, and heat transfer capability for faster heat-up and longer heater life.

Air heater

Strip Heaters are an outstanding industrial heating product and are extremely effective in surface heating applications. They are composed of resistance wire, uniformly coiled and stretched inside a ceramic insulator along the length and width of the heater to ensure uniform heating.

The assembly is embedded in a stainless steel sheath to have high mechanical strength and corrosion resistance, and is filled with high-purity magnesium oxide to remove air pockets and thus provide excellent thermal conductivity and dielectric strength.

Mica Strip Heater

Strip Heaters are an outstanding industrial heating product and are extremely effective in surface heating applications. They are composed of resistance wire, uniformly coiled and stretched inside a ceramic insulator along the length and width of the heater to ensure uniform heating.

The assembly is embedded in a stainless steel sheath to have high mechanical strength and corrosion resistance, and is filled with high-purity magnesium oxide to remove air pockets and thus provide excellent thermal conductivity and dielectric strength.

Coil Heater

Coil heaters offer a high heating profile and high performance in compact spaces up to temperatures as high as 750°C. Available in Various cross-sections and sizes, coil heaters are not only straight and coil form but can be formed into almost any geometrical shape.

Coil heaters can be closely wound to provide concentrated heat or can be stretched to fulfill distributed wattage needs. Coil heaters can also accommodate integrated thermocouples for precise temperature control and quick response. The thermocouple can be of type ‘J’ or type ‘K’ and can be terminated anywhere within the coil section.

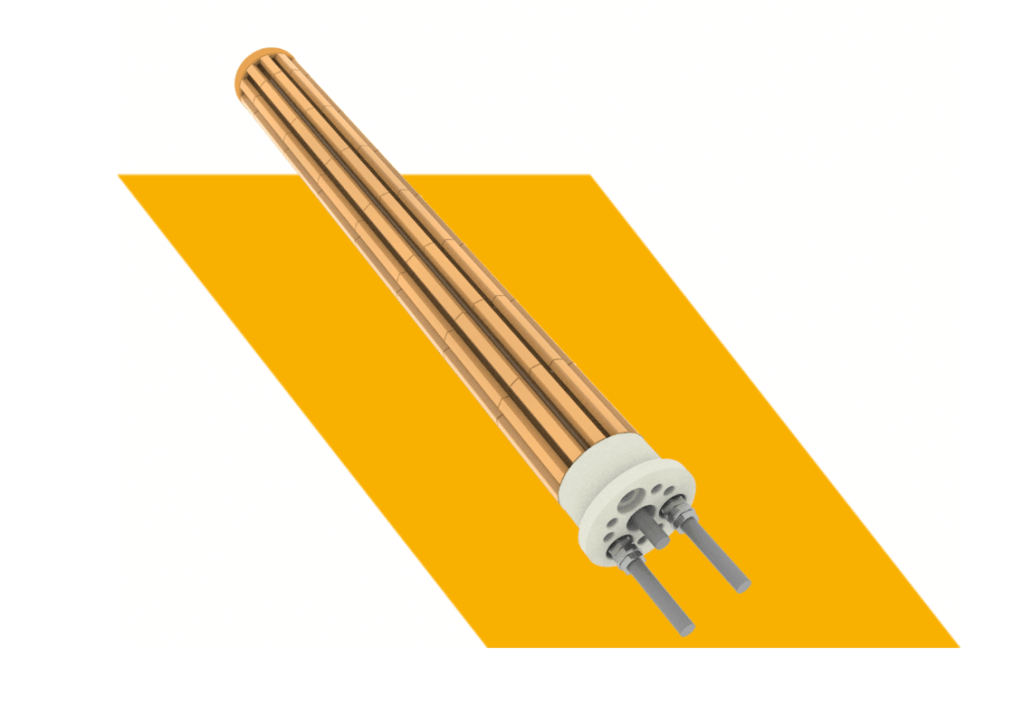

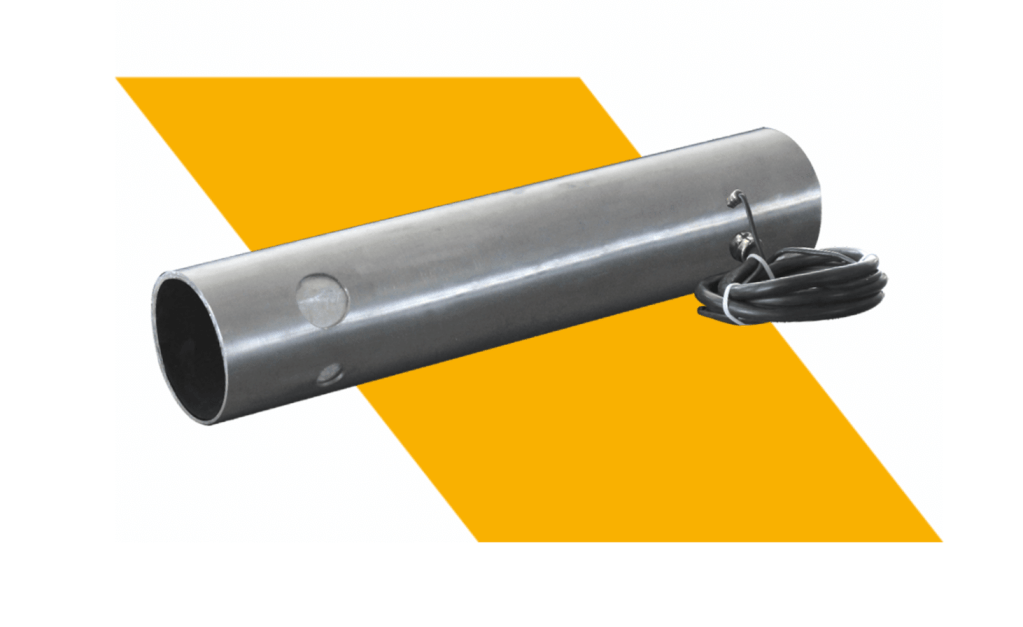

Immersion Heater

A single bundle or multiple smaller units can be installed in the Tank for the uniform heat transfer and steady heating of the fluid, with all safety precautions inbuilt within the heater and control system.

For any Production/process facility, when a large volume of fluid is heated before pumping out to a process application, the Immersion Heaters are always the best-recommended solutions. A single bundle or multiple smaller units can be installed in the Tank for the uniform heat transfer and steady heating of the fluid, with all safety precautions inbuilt within the heater and control system.

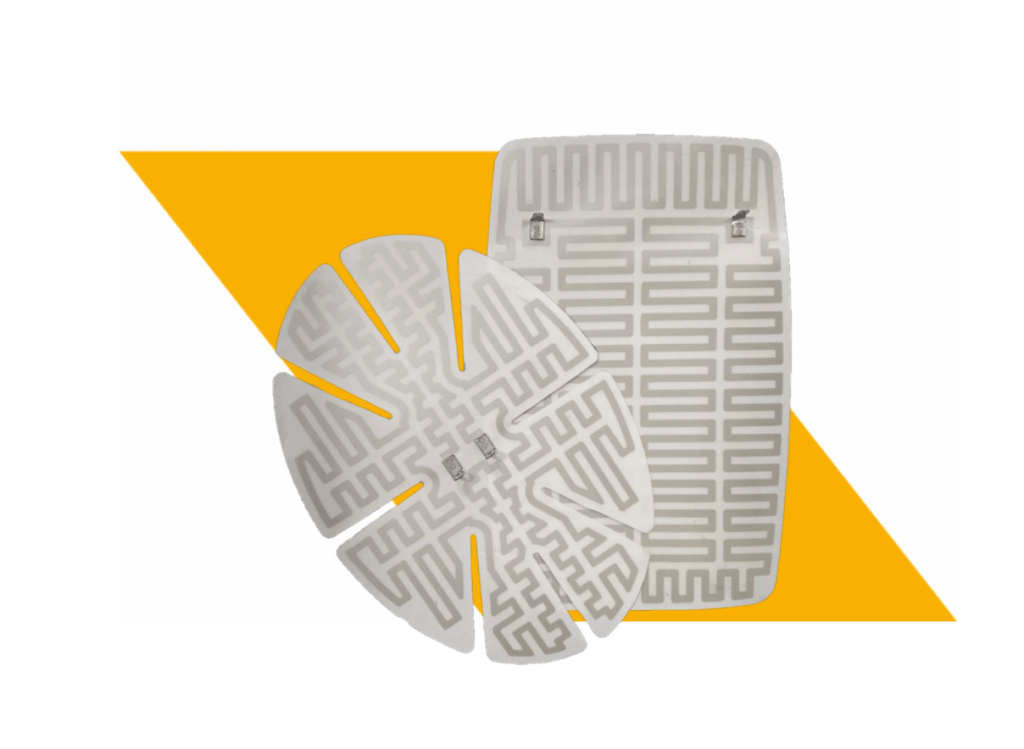

Printed Heater

Printed heaters are made by screen printing a resistor or conductor paste on top of a substrate. It can be directly printed on the surface to be heated, thereby improving the heating efficiency to a great extent. The selection of inks and substrates is determined according to the user application and design requirements. Printed heaters are separated into several categories, such as flexible printed heaters and thick film heaters on ceramic and metal.

Heating Skid Systems

Fuel Gas Heater Skids are a sub-assembly of a complete fuel gas conditioning system or fuel gas filtration package skids. The heating systems are used to preheat the fuel gas to the desired temperature at a specified pressure and flow rate, prior to feeding to the actual process or further circulations.

The specially designed Fuel gas heating skids help to monitor, regulate the gas flow with multiple safety features for trouble-free and risk-free operation. The system is designed considering the incoming gas properties along with environmental conditions to achieve the desired outlet flow conditions.